Whether you call them paper handkerchiefs, or just plain old tissues, facial tissues are a useful and versatile product used by millions of people every day. The convenience of facial tissues, alongside their surprising strength and absorption qualities, makes them very useful at home or at work. A good looking tissue box is definitely a preferable choice. Keeping the box in perfect condition during the manufacturing and packing process is a no compromise requirement for all tissue makers.

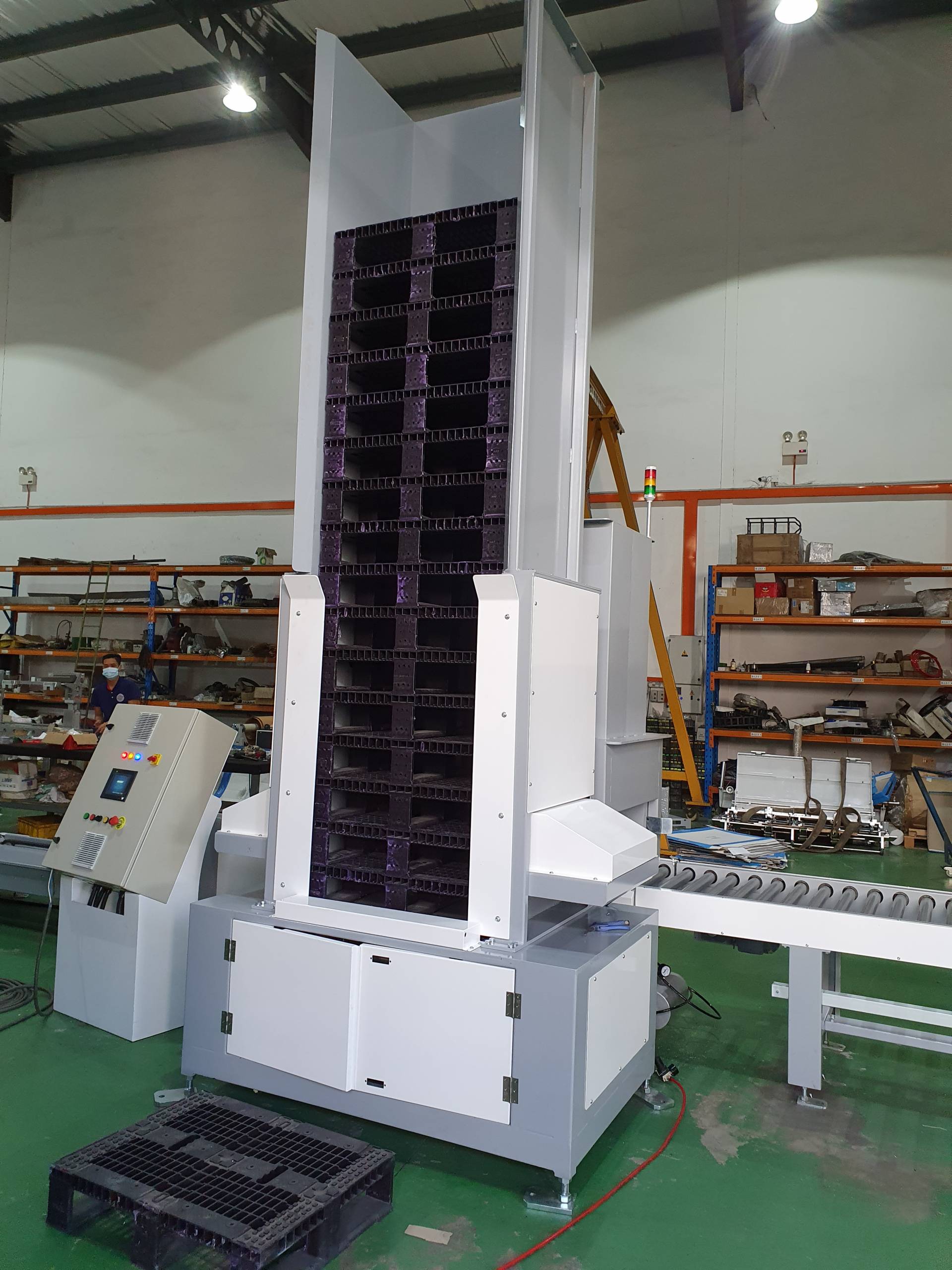

This system is a complete automated solution taking charge from tissue box makers, making a complete tissue boxes loaded stack on pallets at the end. Our method of stacking and palletizing the tissue boxes keeps the tissue boxes in perfect shape while allowing tissue boxes to be transported by pallet. Starting from the tissue box maker, tissue boxes are conveyed one by one using a modular thin conveyor to a batch forming machine, creating an array of 8×10 tissue boxes, then the batch is pushed to a pick and place station. On the other hand, a tray forming machine is used to fold paper cartons into a tray to hold 8×5 tissue boxes on it, and then the tray is transferred to the pick and place station as well. At the pick and place station, a big suction plate is used to transfer the tissue boxes batch and place into the tray. The loaded tray then transfers to the stacker machine. Stacker machine receive loaded trays and a pallet from pick and place station and an automatic pallet dispenser, then stacker machine stacks the loaded tray 5 times, and places a pallet underneath, creating a pallet stack loaded with 5 trays, fully loaded with tissue boxes.

The tissue box packing and palletizing system involves a few standalone machines and conveyors, all controlled by several PLC and inter-connected between them. The package of machines are, different types of conveyors, a ‘Tray Forming’ machine, a ‘Batch Forming with Pick and Place’ machine, a ‘Stacker’ machine, and a ‘Automatic Pallet Dispenser’ machine.